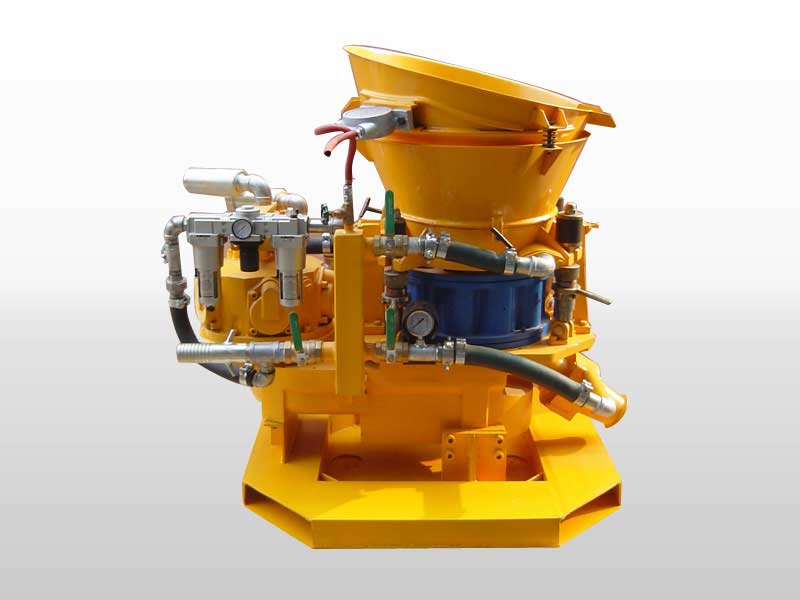

GZ-5 air motor driven dry-mix gunite machine

Output Capacity : 2.5-5.5m3 /h

Max. Horizontal Conveying Distance : 200m

Suitable Mix Ratio(Cement/Sand) : ≤1:3~5

Max. Aggregate Size : Φ15 mm

Conveying Hose Inner Diameterr : Φ51mm

Conveying Pressure : 0.2-0.4Mpa

Need more information?

Contact us for more details about our shotcrete machine, solutions and services.

Leave a Messages

We will get back to you within 24 hours